Above gantry crane was constructed entirely 304 and 316 stainless material. It has 5 adjustable heights in 6″ increments. With 4 position locking stainless steel casters.

Stainless Steel

Gantry

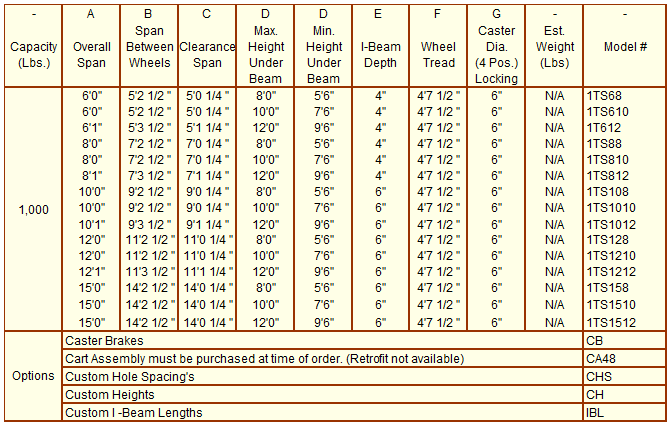

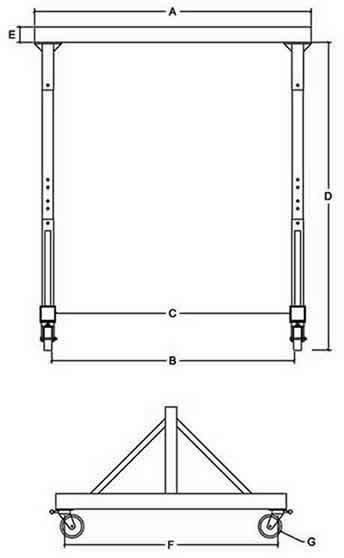

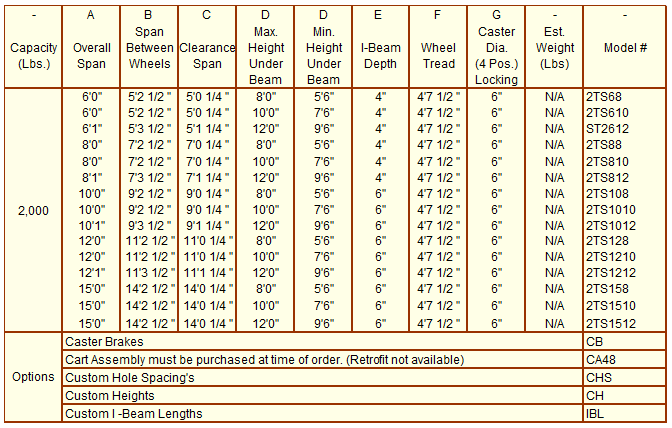

1,000 & 2,000 lb. cap. T-Frame Gantries. 4,000 lb. cap. are available per request along with A Frame Styles

EC&MW, manufacture’s both T Frame and A Frame style stainless steel cranes, although the A Frame model crane is not shown on our website. The T Frames style is by far the more popular design among our customers. Let’s talk about stainless steel for a moment. It is as it says “Stain Less”. You will always have some minor iron deposits at the surface. This was caused at the time the stainless steel was made. Those iron deposits, in time, will turn to rust.

There are two types of stainless steel material that we have available for manufacturing. 304L or 316L . The “L” stands for low carbon. We try to use L material whenever possible/available. Without getting into a lengthy discussion regarding low carbon, it mostly has to do with the welding process. Using L material or non L material isn’t going to make any noticeable difference under most circumstances. 304: We have manufactured gantry cranes for both food and pharmaceutical industries out of this material. Although 316 is more corrosion resistance, since it has molybdenum where 304 does not. 316: Comes at a price. This material is going to be approximately 20% to 25% more expensive and the availability is going to be more limited. We have also built cranes for food, pharmaceutical and sewer treatment facilities from 316. Sewer treatment plants try to use 316 stainless whenever possible, especially in areas where heavy amounts acids and corrosive gases are present. What it really comes down to is what your particular industry standards require. For more info on 304 vs 316 stainless Steel.

Request a FREE Quote

EC&MW Standards:

- We handle all stainless material in the best way possible to avoid any cross contamination.

- When and where it’s necessary, we employ back purging welding procedures.

- Welding is done in combination with both mig and tig welding with 316 wire and filler rod.

- Passivation is performed on accessible welded areas.

- All Stainless steel gantries have in house fabricated stainless steel I beam clamps.

- All hardware (nuts, bolts, washers, etc) are 316. Pins are 17-4PH stainless steel.

- Casters are 304 Kingpinless with roller bearings, 4 position locks with food grade grease on a poly wheel. Unless otherwise specified.

- Like all of our gantry crane systems, these too can be rolled while loaded.

- All stainless steel gantry cranes are crated for shipping, to avoid any cross contamination and or damages.

Note: Not everything we manufacture is posted on our website for all the different models. If you don’t see exactly what you’re looking for, please do not hesitate to contact us so we can help facilitate your needs.

Standard Stainless Steel Gantry Crane Features:

Stainless steel height adjustment handle

5 Position adjustable heights

Adjustable leg widths

Optional Stainless Steel Gantry Crane Features:

Optional caster brakes

Optional custom size I-beam lengths

Optional custom heights upon request

Optional cart assembly available in all models

Optional stainless steel hoists, trolleys

- Certified load testing

Do to the every changing availability and stainless steel prices, all Stainless Steel Gantries Cranes are priced individually. Call for pricing!

Stainless Steel A-Frame style gantries are also available, but just not shown.

Above: This was a custom made stainless steel gantry crane with a 4,000 lb. cap. 15′ beam 12′ height under beam. Completely manufactured from 316 stainless steel including custom stainless steel I-beam clamps. Labeling and gantry cleaning was done after load testing.

Shipping

- Overseas shipping is no trouble. We have shipping world wide for 20 years.

- Note: Shipping is F.O.B. from Elko, NV 89801

- For pricing please contact us by phone 775-778-9112 or fax 866-840-3839 or Sales@ECMW.com

OUR MODEL NUMBERS: 1TS68 1TS610 1TS88 1TS810 1TS108 1TS1010 1TS128 1TS1210 1TS158 1TS1510 2TS68 2TS610 2TS88 2TS810 2TS108 2TS1010 2TS128 2TS1210 2TS158 2TS1510